Skip to content

A cost effective and easy-to-use scale installed on both tracked and wheeled 360 degree excavators to weigh the amount of material in the bucket, grab or clamshell.

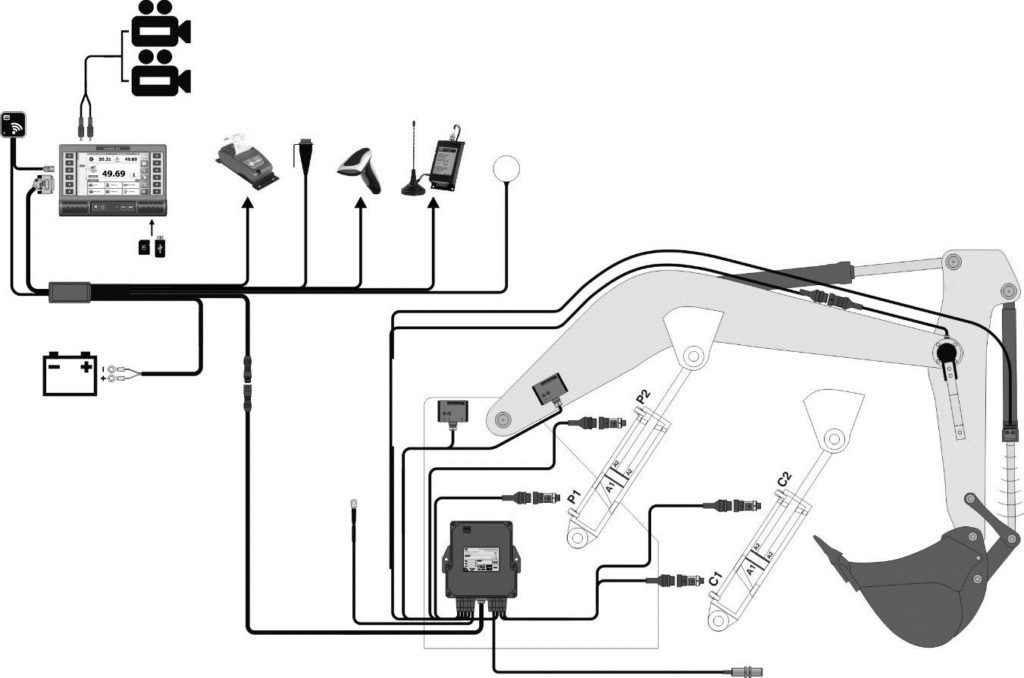

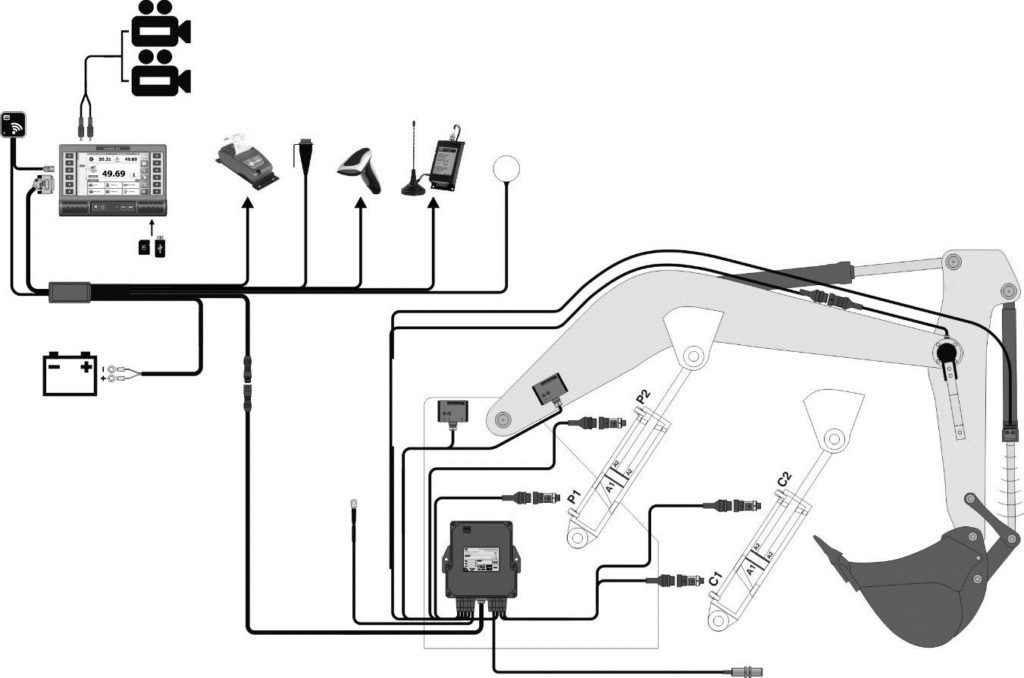

Loadex 100 is an all-new weighing system based on CAN connections for excavators. Position and pressure sensors based on the newest technology are used in the system to ensure constantly accurate weighing in every situation. The temperature sensor of hydraulic oil and the ultrasonic sensor to identify the position of the bucket area available as accessories.

The new LOADEX 100 uses a 7” colour touch-screen display and additional keys providing a modern and ergonomic interface and is easy to use for the driver. 10 different attachments can be calibrated into the memory, which can easily be changed by the driver.

SQL database capability with up to 8 reference fields, provides virtually unlimited inputs of products, customers, trucks, hauliers, locations, destinations, mix blends and notes.

As an option can be installed a printer, a reversing camera, a GPS sensor, and a modem for data transmission.

Features:

-

Colour touch screen display

-

New dynamic weighing technology using inclinometers and a mechanical sensor

-

Hydraulic oil temperature compensation Target load GPS product recognition

-

Reversing camera input Adjustable static or dynamic weighing positions

-

SQL database functionality

-

Stores, multiple job and blend capability with advance memory job search and report function

-

5 memorised quick pre-selections for repeat job set up

-

GPRS and Wi-Fi connectivity

-

Split loading Multi channel and grand total summary

-

XML data output via serial, ethernet and USB memory stick

-

Printer option with configurable output

-

Calibration ‘Nudge’

-

Internal audible alarm

-

System “pause” button

Advantages:

-

Clear, uncluttered display provides intuitive operation

-

Superior weight accuracy and repeatability in difficult conditions and terrains

-

Accurate weight information within normal operating temperatures

-

Set individual product target.

-

Ensure correct loading of vehicles or product

-

Automatic product selection

-

One screen, two functions

-

Flexible according to specific application

-

Ease of use and interfacing with ERP systems

-

Accurate record keeping, traceability & stock management

-

Multiple active job capability

-

One or 2-way communication with back office

-

Truck and trailer

-

Load accumulation for up to 10 attachments e.g. buckets, grab

-

Safe & efficient data handling

-

Hard copy of load summaries, totals, company logo and CE product marking

-

Quick and easy calibration adjustment to match site reference e.g. weighbridge

-

Set to alarm at overload threshold

You can find more information on the excavator weighing scale here: Loadex 100