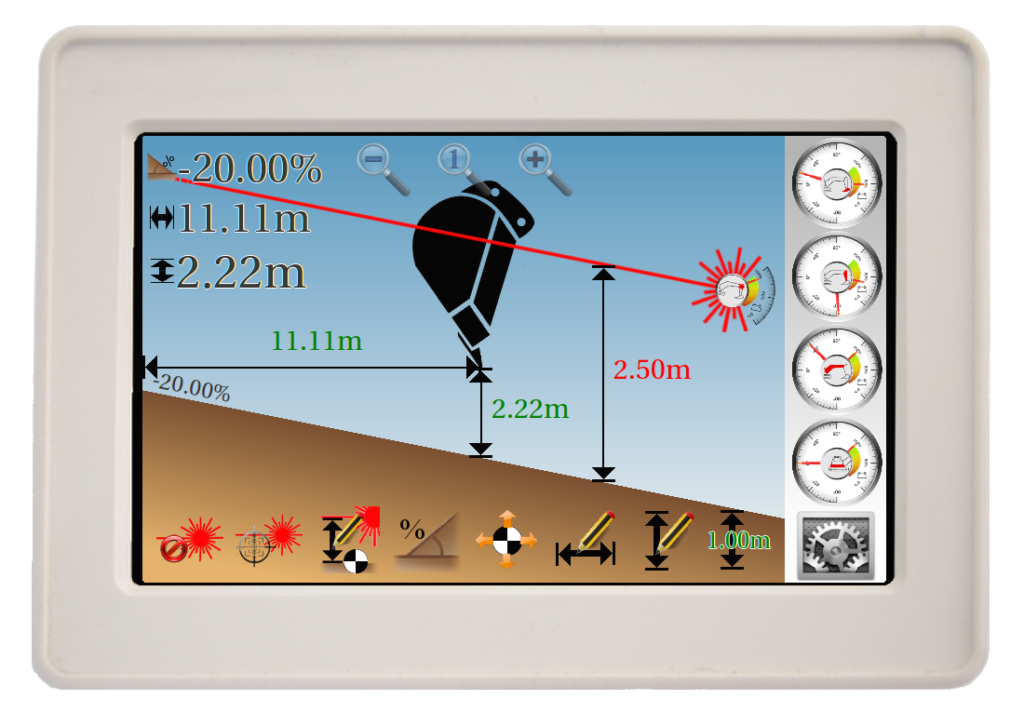

With the iDig system you can manage distances, depths and desired slopes. The combination of advanced technologies is unique in the world: no cables, radio communication, simplified installation and solar charging. The user interface has been designed with excavator operators and can be appreciated by all.

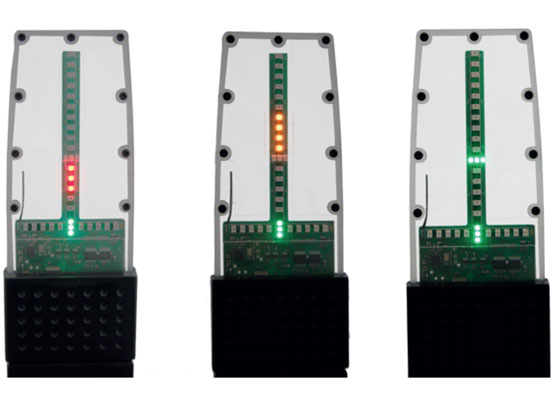

The bargraph and LED display guides you in the same field of vision as your bucket and makes the iDig an ideal daily tool for you.

How works iDig?

Installing the iDig is really simple: attache the 3 sensors, the control box and the LED bar in the cab and start. No need for a technician, you do it yourself by following the on screen instructions. Less than an hour is the average time you need to install the system. Once done, you do not have to do it again. The iDig keeps in memory the exact dimensions of your excavators.

Operator Gets Continuous Real-time Information about Their Depth & Slope (If Used) on the:

-LCD Numerical Display on Power Box

-See-through LED Display: Arrows (Up/Down /“On-grade“) with Real-time Lineal Bar Indication.

Why iDig?

No more over digging. Systems accurancy is better than +/- 1cm.

With the iDig System, You control your excavator without leaving your cab. You will know the position of your bucket to the nearest centimetre and without a grade checker.

Do you have several excavators? Perfect, we made a removable solution that attaches in seconds from one machine to another. The iDig can save as many excavator and bucket profiles as you want.

In the morning you attach on the sensors, the control box and the LED bargraph, then select the right excavator.

Here we go !

If you are interested, be sure to contact us.